This weekend, during the tech festival Bright Day, the Ministry of Defense will show the extend of futurism within the armed forces. Not only with regard to their training methods, but certainly also with a view to the CO2 reduction they achieved in collaboration with CLS-Tex.

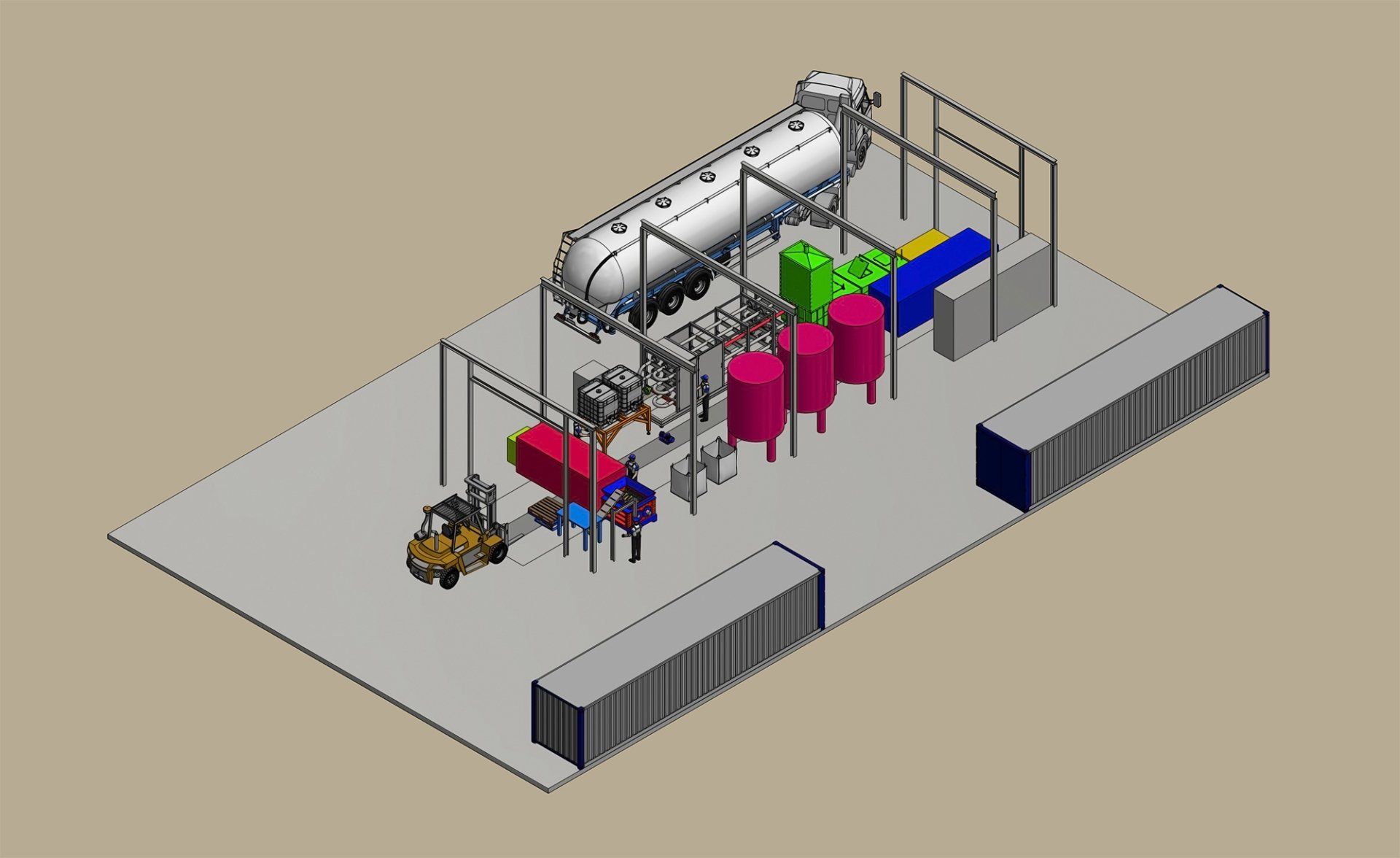

CLS-Tex International, in collaboration with the Ministry of Defense, shows how used clothing from the armed forces is recycled into new raw materials and new products that CLS-Tex returns to the Ministry of Defense.

For example, Defense's has clothing is recycled into yarn to manufacture new polo shirts. But used clothing in combination with old plastic has also been recycled into Cliff granulates. Among other things, road plates, fences and picnic tables have been produced that are now used within Defense itself.

The Ministry of Defense thus demonstrates that waste is not waste, but a raw material for new products for the armed forces. Defense creates savings on CO2 emissions with a positive impact on the environment. It has been calculated that all Defense clothing that is recycled into new raw materials and products yields a CO2 saving that is equal to the annual CO2 emissions of an important city in the Netherlands.

'DefLab', a glimpse into the future of the armed forces

These good developments for the future have already started today and will become visible on November 23 and 24 during the Bright Day tech festival, Expo Haarlemmermeer. Defense shows much more there. For example, innovations within the armed forces are visualized on the 'Deflab Square'. This concerns gadgets in the field of future mobility, future warfare, robots and superhumans and future sustainability.

Visitors can get acquainted in an interactive way with, for example, the cargo drone, E-bikes, recycled clothing, serious gaming, virtual reality, augmented reality and mixed reality training resources.

Share this news item

Read about our innovations, developments and co-operations

In 2012 Jukka Pesola (Pure Waste) and Rien Otto (CLS-Tex) met as winners of the ‘2012 Challenge Solution Textile’, set by the global innovation platform ‘LAUNCH Nordic’. From then on the two pioneers started working together. Recently they agreed on taking the next step and start closing the loop by presenting the extended label Pure Waste CLS Inside. Pure Waste products are initially already made from recycled textile. However, after their use they will be given yet another life: using the innovative HTEX technology, used clothing is being recycled into raw material for new yarns, fabrics and new garments. The return and recycle services as well as the recycling process are made possible by CLS-Tex’ innovative solutions. This way the loop will be entirely closed: waste will be raw material!